G1 Corn to Ethanol Technology

Commercial production of ethanol involves breaking down the starch present in corn into simple sugars (glucose), feeding these sugars to yeast (fermentation), and then recovering the main product (ethanol) and byproducts (e.g., animal feed, starch, crude corn oil). Two major industrial methods for producing are used: wet milling and dry grind. Drygrind ethanol production represents the majority of ethanol processing, and all newly constructed ethanol plants employ some variation on the basic dry-grind process because such plants can be built at a smaller scale for a smaller investment.

Dry Grind

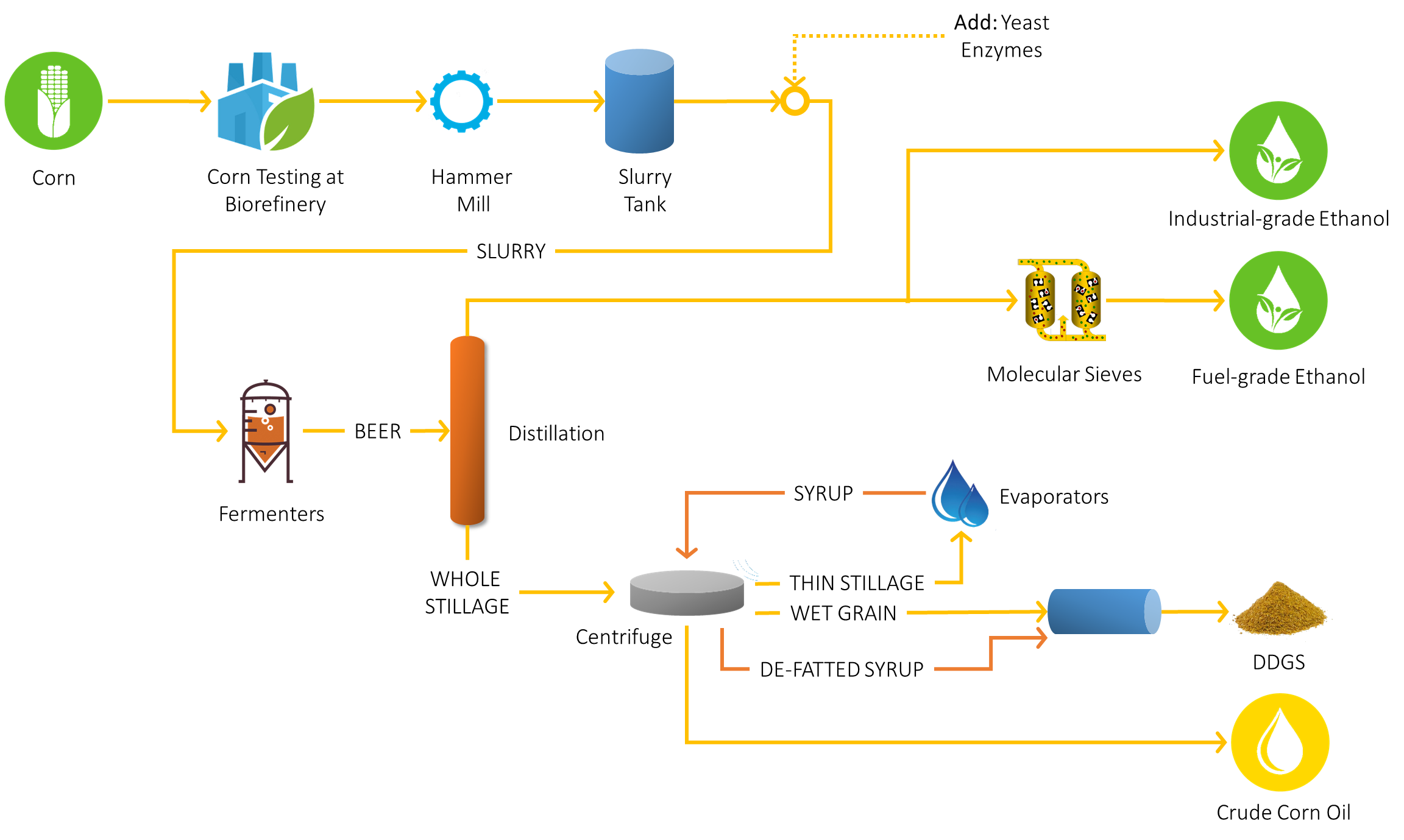

In the dry-grind ethanol process, the whole grain is processed, and the residual components are separated at the end of the process. There are five major steps in the dry-grind method of ethanol production:

- Milling

- Liquefaction

- Saccharification

- Fermentation

- Distillation and recovery

Milling

This step involves processing corn through a hammer mill to produce a corn flour.

Liquefaction

At this point, slurry from milling is cooked, this is accomplished using jet-cookers that inject steam into the corn flour slurry to cook it at temperatures above 100°C (212°F). The heat and mechanical shear of the cooking process break apart the starch granules present in the kernel endosperm, and the enzymes break down the starch polymer into small fragments.

Saccharification

After liquefaction, the slurry, now called “corn mash,” is cooled where enzyme completes the breakdown of the starch into simple sugar (glucose). This step, called “saccharification,” often occurs while the mash is filling the fermenter in preparation for the next step (fermentation) and continues throughout the next step.

Fermentation

In the fermentation step, yeast is added to the corn mash to begin the process of converting the simple sugars to ethanol. The other components of the corn kernel (protein, oil, etc.) remain largely unchanged during the fermentation process. In most dry-grind ethanol plants, the fermentation process occurs in batches. A fermentation tank is filled, and the batch ferments completely before the tank drained and refilled with a new batch. The up-stream processes (grinding, liquefaction, and saccharification) and downstream processes (distillation and recovery) occur continuously (grain is continuously processed through the equipment). Carbon dioxide is also produced during fermentation.

Usually, the carbon dioxide is not recovered and is released from the fermenters to the atmosphere. In our process, this carbon dioxide is processed, compressed and sold for carbonation of soft drinks or frozen into dry ice for cold product storage and transportation.

After the fermentation is complete, the fermented corn mash (now called “beer”) is emptied from the fermenter into a beer well. The beer well stores the fermented beer between batches and supplies a continuous stream of material to the ethanol recovery steps, including distillation.

Distillation and Recovery

After fermentation, the liquid portion of the slurry has 8-12% ethanol by weight. Because ethanol boils at a lower temperature than water does, the ethanol can be separated by a process called “distillation". Conventional distillation/rectification systems can produce ethanol at 92-95% purity.

The residual water is then removed using molecular sieves that selectively adsorb the water from an ethanol/water vapor mixture, resulting in nearly pure ethanol (>99%).

The residual water and corn solids that remain after the distillation process are called “stillage". Stillage is then centrifuged to separate the liquid (thin stillage) from the solid fragments of the kernel (wet cake or distillers’ grains). The remaining thin stillage passes through evaporators to remove a significant portion of the water to produce thickened syrup. Usually, the syrup is blended with the distillers’ grains and dried to produce an animal feed called “distillers’ dried grains with soluble” (DDGS).

G1.5 Technology

As was explained previously, first generation (1G) facilities produces bioethanol by fermenting sugars from sugar cane, sugar beet or cereals seeds, whereas a Second Generation (2G) facility uses sugars found in lignocellulosic biomass (agricultural residues, lignocellulosic crops…). There is a special mode of hybridization that take advantage of the cellulosic sugars hidden in the corn kernel fiber. Known commonly as 1.5 Generation (1.5G), the ability to convert corn kernel fiber to ethanol is the bridge the gap between the production of ethanol from corn and cellulosic ethanol.

Corn fiber to ethanol technologies are being rapidly adopted by corn ethanol refiners who are attracted by the rise of ethanol and corn oil yields. Our process is fully developed and oriented to G1.5, taking the advantage of the conversion of the corn kernel fiber to obtain a highest yield, improving ethanol production for all the projects developed with our technology.